MOLECULAR COMPANY

Changchun Changrui Automobile Stamping Co., Ltd.

Changchun Changrui Auto Stamping Co., Ltd. was invested and built by Changchun Auto Stamping Co., Ltd. in Changchun Chaoyang Economic Development Zone in 2000. The company covers an area of 166,000 square meters and has been awarded the title of “National Double Love Double Evaluation Advanced Unit”. "Jilin Province Small Giant Enterprise" "Changchun City Key Support Enterprise"

The company mainly produces stamping, welding and painting parts for FAW-Volkswagen, FAW Toyota, Magna, Bentler Changrui and other customers. The main products are car dashboard skeleton assembly, pedal mechanism assembly and A-pillar assembly. More than 100 kinds of B-pillar assemblies and bumper skeleton assemblies

The company has strong technical strength, has the ability to develop synchronously with the OEM, and applies CATIA 3D software for product design and tooling mold design. Apply Autoform simulation analysis and build a mold processing base.

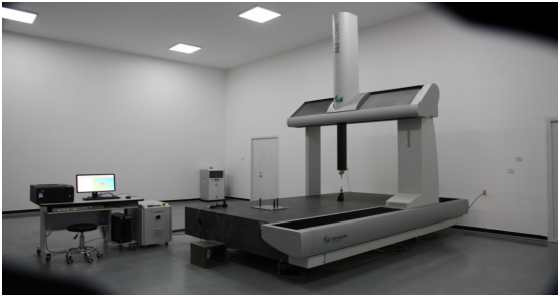

The advanced and special process equipment, high degree of automation, and especially through the introduction and digestion of foreign advanced technology, further enhance the company's ability to innovate. The main process equipment is 158 sets/sets. There are 5 stamping production lines consisting of 1600 tons and 1250 tons of punching machines. The main assembly robots from Germany, the central controller of Germany, and the electron beam robots form 10 welding production lines. The company has one domestic large-scale cathodic electrophoresis coating production line and one cleaning line. The company has a complete set of testing methods, physical and chemical testing, product performance testing, D (safety) functional test, three-coordinate measurement and other types of inspection and testing equipment 238 sets / sets, in 2011 was named provincial-level enterprise technology center.

In order to meet the requirements of the OEM, it has passed ISO9002, VDA6.1, QS9000, IOS/TS16949 quality system certification and ISO14001,18001 environmental health and safety system certification. And through the FAW Group, FAW Volkswagen Company A-level certification. The company strives for excellence in quality, and strives for excellence in service. It has won unanimous praise from users and won its own development.

PRODUCTION EQUIPMENT

Professional attitude, invite you to witness

1. Stamping production line

Stamping production line

2.Welding production line

Pedal arm welding production line

Suspension spot welding machine welding production line

3. Coating production line

Cathodic electrophoresis coating production line

4.Quality assurance

Experiment apparatus